In this series we take robot innovations from their test-lab and bring them to a randomly selected workplace in the outside world. This time we look at radioactive sensory robot Christine. Suppose it would venture beyond the hospital, into the hospitality industry? We find that Christine could raise staff spirits, while maintaining discipline at the same time.

RoboHouse Reads. Listen to an audio version of the article here.

Patients are sometimes injected with radioactive fluids as part of diagnostics. When radioactive fluid accidentally gets spilled during this procedure, this can cause a health hazard in the workplace. When cleaned manually, the staff can accidentally spread the contamination even further and over a broader surface. The Reinier de Graaf Hospital in Delft decided to look towards cognitive robotics to avoid this health risk. They asked team PRISTINE of the TU Delft minor robotics program, to automate the cleaning of radioactive spillage. The diverse team of students worked together for five months to build a working prototype.

It will have the spillage sorted in about an hour. Floris van Mourik, electrical engineer at team Pristine

We met the team in January during Demo Day at Robohouse where they presented Christine. “If a small amount of radioactive liquid is spilled, hospital workers usually know where the contamination is roughly located, but not exactly”, says electrical engineer Floris van Mourik. “Therefore they clean at the estimated location. With a detection device they will check if radioactivity can still be detected. Our robot can simply be put down in a room. And it will have the spillage sorted in about an hour.”

To make Christine fulfil its purpose in a hospital, three key features were implemented in this first prototype version.

Robot strength 1: Sensors on every wheel

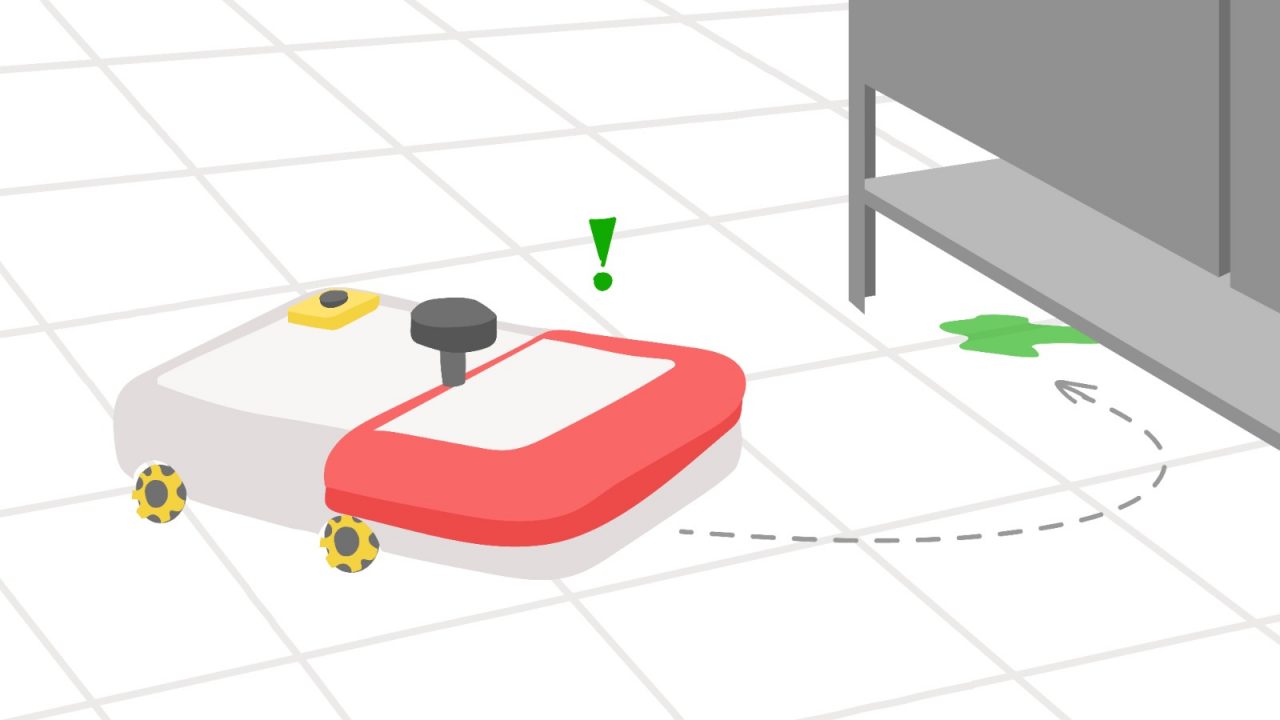

The bottom of the robot holds a big radioactive sensor. With this, the robot is able to steer itself in the direction where the radiation is strongest. To avoid driving through the radioactive fluid and causing further contamination, Christine has four smaller geiger counters mounted near the wheels. By comparing the measured intensities of the different sensors, the robot can find the exact location of the spillage. Once there, the cleaning process is triggered. Oscar Wamelink, mechanical engineer, explains: “When that happens, the cloth on the bottom of the robot descends to the floor and cleans the spot.”

Robot strength 2: Wheels for infinite mobility

Another feature that separates Christine from a regular cleaning robot are its wheels. To avoid driving through spilled liquids with either one of the four wheels, the robot has to move around easily. This is why the team chose to use Mecanum wheels.

Van Mourik grabs a laptop and puts it on the floor to visualise how this works: “With regular wheels you can move only forward and backward”, he explains while moving the laptop in the corresponding directions.

It can rotate around its own axis too. Mickey Wong, industrial design engineer

“With the Mecanum wheels we can also move directly to the left and to the right, without making a turn like a car or shopping cart,” adds Mickey Wong, industrial design engineer. “It can rotate around its own axis too. Using these wheels, the robot basically has an infinite degree of mobility.”

The team also implemented a sensor on top of the robot that maps the location and tracks where it has been. As a result, the robot can efficiently reach every location in an area to search for radioactive material.

Robot strength 3: User-friendly interface

“The robot is very user-friendly”, says Wong, pointing out the coloured light system that Christine has for communicating with its environment. “When the device blinks in green, the operator knows it has found the contamination. Blue tells you the robot is still searching. There are also colours for indicating that Christine is finished, or has found the spot but was unable to clean it: for example, when the spillage is located under a cabinet.”

Blue tells you the robot is still searching. Mickey Wong, industrial design engineer

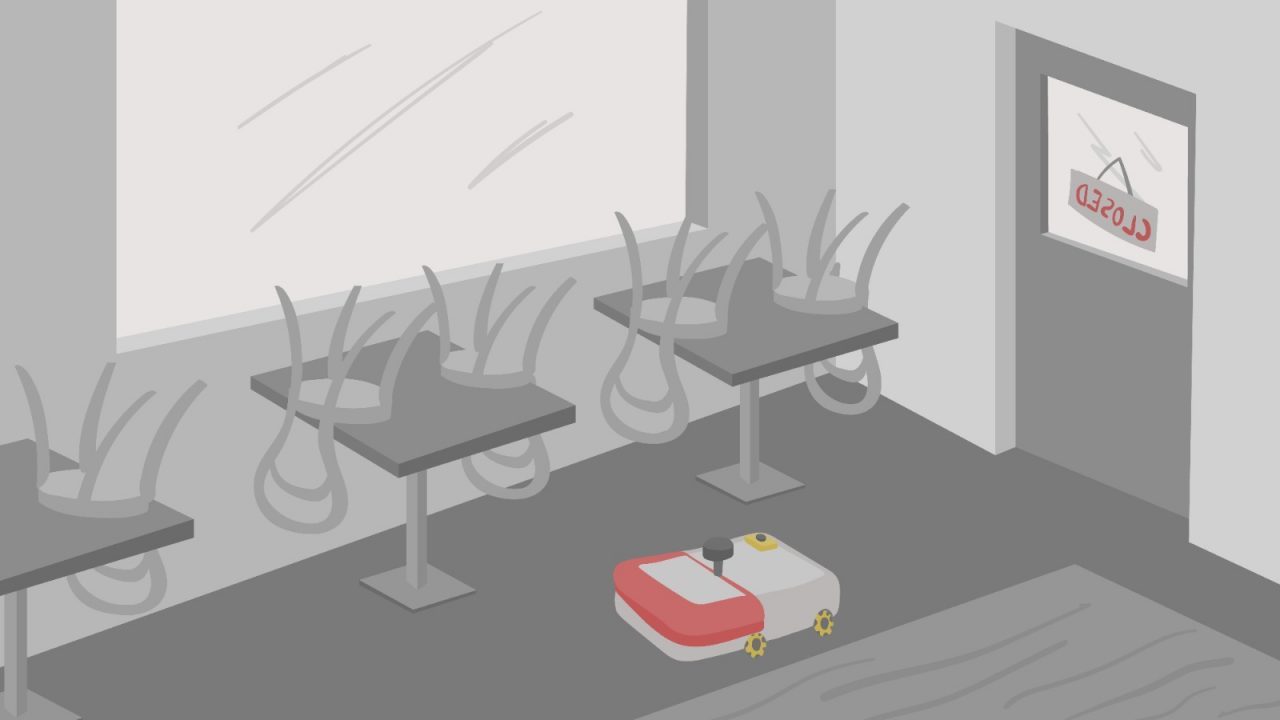

Robot Christine in Café LUX : What if you would use this?

The prototype of robot Christine appears promising for health improvement of hospital workers. However, innovations often do not end up where they were once intended to go. What if we extract this robot from its destined environment, and consider its applications in another field of work? This brings us to Yves Snijckers, a waiter at Café LUX in Nijmegen. We asked him: What if you would use this?

Yves Snijckers is a molecular life sciences student by day, and a waiter at Café LUX by night. The catering facility belongs to the LUX arthouse cinema in Nijmegen and the ambience is usually casual and welcoming. Most guests come in for a drink or bite after enjoying a movie or theatre performance. “There are two sides to this job”, Yves tells us. “On the one hand, as a host you want to create a cosy atmosphere. On the other hand, you need to work very disciplined to keep the business running.”

There are two sides to this job. Yves Snijckers, waiter at Café LUX

As someone who feels very at home in the hospitality industry, Yves has a clear opinion regarding robots in this working environment. “A robot moving through LUX would be a bit weird”, he laughs. “A bit of a turn-off perhaps. On the other hand: it would be nice to have a little help sometimes. Especially on those days where everything seems to be going wrong.”

When Yves thinks about it a little longer, he starts to visualise possible purposes for this seemingly specialised robot.

Yves idea 1: Smart after-hours mop

After closing time, the robot could roam free. Yves Snijckers, waiter at Café LUX

“The most obvious new purpose for this robot would be using it as a smart cleaning device after working hours”, says Yves. “During the day, a robot like this would mostly get in the way of the guests and staff. After closing time however, the robot could roam free to clean, which could save us some late-night work.” Many robotic mops and vacuums do not have smart navigation methods and move quite randomly through an area. Christine’s location sensor would make for a robotic mop that could navigate the more challenging surfaces of a restaurant, like narrow corridors behind the bar or in the kitchen. Avoiding driving through contaminations is also a useful feature. No one wants to find their floor full of smears and streaks in the morning, a common problem with regular cleaning robots.

Yves idea 2: Objective inspector

The way to the warehouse is a real maze.

Yves Snijckers, waiter at Café LUX

Yves thinks Christine could also be used as the hygiene equivalent of a spell checker: searching for dirty areas and marking these. “The consequences of an uncleaned spillage in the hospitality industry are probably a lot less severe than in hospitals. But our hygiene must always meet national standards”, says Yves. “Therefore, it could be useful to have a device that can objectively check hygiene levels in a café or kitchen.” In this scenario, the staff can clean manually as usual, put down the robot for an objective check and then return to areas that fail to meet hygiene standards according to the robot.

Yves idea 3: Wheels transfer

When we circle back to the specific strengths of this robot, Yves is struck by a new idea. “What if we would take the wheels of the robot and put these on our stockroom trolleys? We sometimes need to replenish the stocks in the café. But the way to the warehouse is a real maze, and there are a lot of tight turns”, Yves explains. “It would be really nice if the wheels of the trolleys could move in all directions instead of just back and forth.”

Following this train of thought, he dissects the robot even further: what about using the robot’s mapping ability to plan the layout of the café? A while later, even a purpose for the sensors can be found in the café. “Not for tracing radioactivity of course”, Yves laughs. “But especially during times of Covid, checking the indoor air quality is very important.”

‘The other half of the story’

Yves’ new purposes all have one thing in common: helping the staff balance between working disciplined and maintaining a good atmosphere. Where will the robot of team Pristine eventually end up? That’s up in the air. She might roam hospital rooms in search of radioactive materials, work as a hygiene inspector, or she may lose some of her parts to upgrade other tools.

Sometimes you forget that not everyone is an engineer.

Luis Alcantara, mechanical engineer at team Pristine.

What do the robot’s designers think of these possible futures? We took Yves’ ideas back to the lab and noted their response.

Luis Alcantara, mechanical engineer, says: “Sometimes there are situations where you kind of forget that not everyone is an engineer. So, you only see part of the story. And when someone shows you the other half, it’s always a surprise, but in a very interesting way. Because next time, I guess you learn to think about the people who are going to use it.”