The nearly $100m Chrysalix RoboValley Fund invests in young companies across the globe that are developing technologies in intelligent systems, resource productivity and environmental solutions for resource intensive industries such as energy, mining, mobility, construction, chemicals and materials, and manufacturing.

“We want to highlight to the RoboHouse community that we have money,” says Alfred Lam, a partner at Chrysalix who ten years ago transitioned to venture capital after a career in R&D at Clean Energy Research Centre (CERC) of The University of British Columbia. “Also good to know for entrepreneurs and developers: with this fund we are able to take more risk. Probably more than your traditional funder.”

“We have money, and we are able to take more risk.” Alfred Lam, partner at Chrysalix

Investors in the fund include Fortune 500 companies, leading corporates, financial institutions, family offices and universities such as Delft University of Technology. It already has stakes in over 10 start-up firms and developers.

With our special interest in the future of work, and how cognitive robotics could serve the needs of the workplace, one of the current beneficiaries of the Chrysalix RoboValley Fund stands out: Applied Impact Robotics.

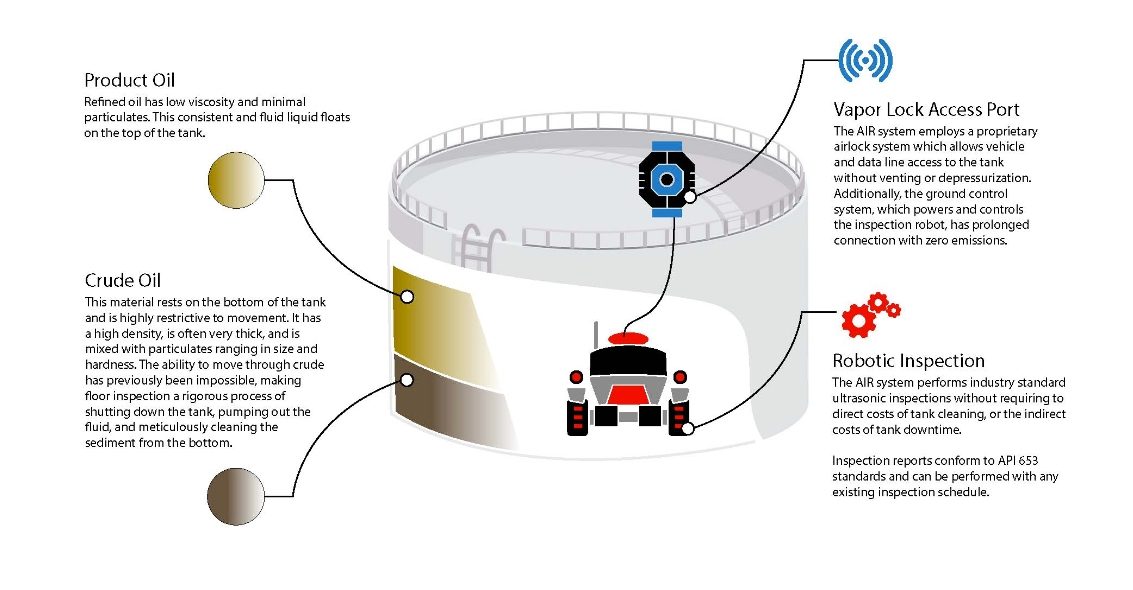

On its site near the waters of Potomac Falls in Washington DC, Applied Impact Robotics is developing a robotic solution for inspecting a crude oil tank floor while the tank remains in-service.

Traditional inspection demands oil storage tanks to first be taken offline, drained and cleaned. Then a human crew enters to look for any damage that must be repeared. It is an expensive process and bad for the environment too – since part of the drained crude oil is disposed as chemical waste.

The problem is the thick sludge that sits at the bottom of the oil tank. Fred Briggs, president and CEO at Applied Impact Robotics

Fred Briggs, president and CEO, says: “Inspection of oil storage tanks is not just costly, it is also dangerous and dirty work. You’re in a closed space, threatened by rusty metal beams, toxic fumes and slippage. Crews must be wearing full respiratory suits. So there is a case to try something else. But the problem is the thick sludge that sits at the bottom of the oil tank. Most alternative solutions have tried pushing a device through it. This always fails.”

In the summer of 2019, Fred and his team happened upon a potentially breakthrough solution when they competed for the Chrysalix Tank Inspection Challenge, which promised to award $250k to “innovative ideas for safe, accurate and economical inspections of aboveground storage tanks without human entry, while staying in service”. They applied on a goof and put their whole submission together in three days. And won.

Our solution uses a process called liquefaction. Fed Briggs, president and CEO at Applied Impact Robotics

Behind the success was a blend of factors. First of all, they presented a very novel approach. Fed Briggs says: “Our solution was nothing like anything out there. It uses a process called liquefaction. The robot sucks in fluid from the top of the tank, injects it into the sludge and vibrates to reduce viscosity. This then allows the robot to propel itself forward through the sludge, which temporarily behaves like a liquid.”

It was the science fair thing that got investors excited. Fed Briggs, president and CEO at Applied Impact Robotics

The second factor was the humble and effective way Fred and his team pitched their idea. With less than $100 of materials they managed to demo the essence of their vision to potential customers and the Chrysalix Tank Inspection Challenge jury. “We built a simple table top demonstrator that turned sand into a liquid,” says Fred. “Like a science fair demo. Just one bucket of sand, a vibrations module and some water. This resonated really well with people. We also had a much bigger demonstrator, but it was the science fair thing that got investors excited.”

Winning the Tank Inspection Challenge and then landing Chrysalix funding means that Applied Impact Robotics now looks set to disrupt a global inspection market that has been mired in stagnation for more than three decades. “Vopak would be an ideal customer for Applied Impact Robotics,” says Alfred Lam. Royal Vopak is the world’s leading independent tank storage company. With headquarters in Rotterdam, 25 minutes by car from the TU Delft Campus, Vopak indeed looks perfectly positioned to secure a partnership once the Chrysalix backed firm is ready to scale.

If you are a creative company like Applied Impact Robotics and looking for new ways to move forward, the Chrysalix RoboValley Fund could be a source of inspiration and energy.

Vopak would be an ideal customer for Applied Impact Robotics. Alfred Lam, partner at Chrysalix

We have found this fund to be highly approachable. Alfred Lam lives in Delft and has a cosy corner office in RoboHouse. You can always contact him for a friendly chat. How? Send a text message: +31 6 13 728 643. (Indeed, Alfred is still too much of a shy R&D guy to answer direct calls.)