Each young patient in a Neo-natal Intensive Care Unit (NICU) needs multiple syringes of milk per day, and in a large hospital like Erasmus MC that task certainly adds up for the nurses. So how did Neollie take on this challenge, evolving from student minor to business venture? And what is their connection with a certain well-loved elephant?

A team of young specialists

Neollie was founded by four TU Delft students with diverse expertise. Caya Huijbregts, a mechanical engineering student, handles operations and machinery. Computer science students Gabriel Tertelici and Karol Sperczyński manage software, quality management and strategy, while Guus Hak, studying electrical engineering, oversees hardware, finance and legal matters. The team works with pediatrician Tom Ouwehand who balances his work at the Erasmus MC with Convergence; a joint initiative with TU Delft advancing healthcare innovation.

The problem: hours lost in the kitchen

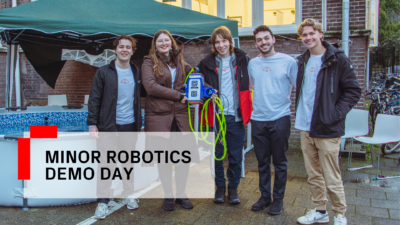

Neollie’s story began when the students joined the TU Delft Robotics Minor at RoboHouse; a course where companies can present a problem or situation they are facing, which the students then tackle using robotics. Tom represented Erasmus MC, and described a demanding layer of work in NICU wards: nurses are tasked with carefully preparing hundreds of doses of milk, adding specific amounts of fortifier powder to support the growth of the babies in their care.

“It takes 4-5 hours per day for two nurses to mix the doses”

As Guus explains: “Just for preparation in the hospital in Rotterdam, it takes 4–5 hours per day for two nurses to mix the doses. They’re just sitting in a kitchen preparing like 420 milk syringes.” The task is unpopular, prone to fatigue, and adds to the already heavy workload. This is where Neollie’s first product, Neo, comes in.

Neo: a little less conversation, a little more action

Neo is an automation system designed to prepare, dose, and fortify breast milk. Nurses simply deliver a bottle of milk to the machine, which then measures the fortifier, mixes it, distributes doses into syringes, and stores them safely in cooling. When it’s time to feed, the syringes can be warmed to body temperature for administration.

Designed for reliability, the machine uses sensors to verify bottle placement, scales to ensure dosing accuracy (of up to 0.005 g), and mixing to achieve homogeneity. These automated processes deliver more precision than manual scooping and measuring, showing strong potential to outperform manual preparation and free nurses to focus on patient care. While Neo may not function faster than a nurse would, it can run for more hours without feeling the burden of repetition, and it can provide feeding doses on time with a capacity of about 60 syringes per hour.

“If you tell people that something is a robot, they seem to expect a humanoid”

Feedback from Erasmus MC has been very positive and, on occasion, surprising. “There were a few interesting demands” Karol recalls, “for example the fact that they expected it to talk. We started out calling it a robot but eventually started calling it a machine. We found that if you tell people that something is a robot, they seem to expect a walking talking humanoid”.

A bumpy road from prototype to company

When team Neollie finished the minor program, they knew they were on to something bigger. However, starting a company doesn’t happen overnight. As Caya put it, “We’ve faced every challenge, basically”. From marketing to legal obligations, the learning curve has been steep. Guus adds “there’s a lot of things you just don’t know at the start, especially in legal terms. It all feels like ‘what is this? I don’t know, but if you don’t do it, you get a fine’”. Luckily, Karol maintains that their confidence has been rising over the months. “The team works very well together, which makes all the difference. We can trust each other to make the right decisions, and as the to-do list shrinks a bit, we can focus on further developing the robot”.

As they learn more about the ins and out of self-employment, a motto has taken shape “Do it once, but do it right.”

What about that elephant in the room?

“We always used to say ‘Let’s meet at Olli’ “

The name Neollie traces back to the roots of the team’s research at the Sophia children’s hospital of Erasmus MC. On a platform central to this building stands a 2m tall plastic elephant, round as a ball, with bulging eyes, and its name is Olli. “It’s like a Rotterdam icon, an ambassador for children,” Caya explains, “so this giant round elephant stood in the hospital, and we always used to gather there because it was easy to find. We always used to say ‘lets meet at Olli’”. Combining the ‘neo’ of neo-natal with the name of the iconic elephant, ‘Neollie’ was born. Olli also happens to be the mascot of the renowned Rotterdam football club Feyenoord, further fortifying Neollie’s origins in the Rotterdam-based Erasmus MC.

What’s in store for Neollie?

Neollie is currently working towards one main milestone: within three years, the students want to construct a product that can be deployed, or at least thoroughly tested, in a hospital setting. Before this can happen, they want to make sure that Neo is completely ready to provide accurate and safe care to the vulnerable young patients that would depend on it.

On the topic of what success would look like for Neollie, Guus has a clear definition: “If we really sell it, even just once, it will feel like a success. It may not be a success in business terms, but for me as a person, I can know that I have brought a real product to the market.”

While they develop the company, team Neollie has been welcomed into the test centre at RoboHouse where they have grown in a well-connected and experienced ecosystem. Together with RoboHouse and Erasmus MC, they have also secured the WorkTech grant from the Medical Delta innovation program, which focusses on solving the staff pressures in healthcare environments.

As they continue their journey with the dedicated that they have shown over the past months, we can’t wait to see how Neollie grows.

Dit project is mede mogelijk gemaakt door Kansen voor West – Voucherregeling fieldlabs TU Delft Campus, en is medegefinancierd door de Europese Unie.