During the TU Delft Minor Robotics of 2024-2025, eight enthusiastic student teams worked on a robotic prototype, commissioned by a company. Meet the teams below!

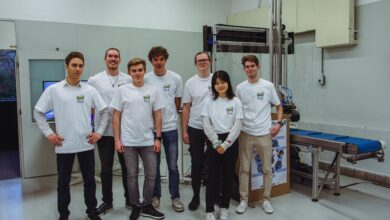

Team 1 Botter

The Automatic Fat Block Unpacking Robot

The Automatic Fat Block Unpacking Robot unpacks 10-25 kg fat blocks used in the large-scale pastry industry. It employs a 2D gantry system with a custom gripping solution to remove the plastic wrapping. The removed plastic is deposited into a waste bin, ensuring efficiency, maintaining hygiene, and reducing manual labour.

Team 1 – The Automated Fat Block Unpacking Robot

This project is commissioned by Rademaker.

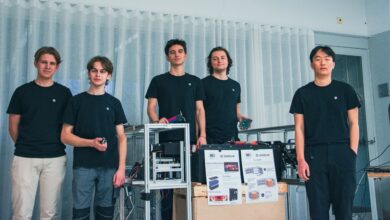

Team 2 SPADE

Subterranean Powerline Automated Dynamic Excavator

The Subterranean Powerline Automated Dynamic Excavator (SPADE) robot aids in improving working conditions and underground infrastructure maintenance by being an automated solution for safe excavation of trenches for cable access in the Netherlands. It explores the place of suction in the industry and effectiveness of digging with robots.

Team 2 – SPADE

This project is commissioned by Alliander.

Team 3 MANTA

MANTA

MANTA is an autonomous underwater robot that revolutionises offshore inspections, employing an ultrasonic sensor and depth camera alongside innovative techniques to precisely assess mooring systems and metallic surfaces, enhancing safety and efficiency.

Team 3 – MANTA

This project is commissioned by Weed Wonders.

Team 4 The ABC robot

The Automated Battery

The ABC Robot streamlines end-of-line testing for heavy-duty batteries designed for Sandvik’s mining machinery. Once a pallet carrying the batteries is delivered, the robot autonomously connects the chargers and coolant lines, initiating the testing process.

Team 4 – SANDVIK Automated Battery Connector

This project is commissioned by Sandvik.

Want to be part of the 2025-2026 cohort of the Minor Robotics?

Contact Astrid van der Niet

Team 5 BladeGuard

The BladeGuard Robot

The BladeGuard robot is developed to install sensors inside wind turbines. It drives into the blade, prepares the surface, glues down the sensor and mounts its data cable. Usage of the robot allows for deeper sensor placement and safer, less labour intensive operations.

Team 5 – BladeGuard

This project is commissioned by TNO.

Team 6 Robottler Neo

The Robottler Neo

The Robottler Neo automates feed preparation for babies in the NICU by storing, cooling, mixing, and dosing milk and fortifiers, hereby ensuring precision, safety, and efficiency. It minimizes nurse workload and enhances patient care.

Team 6 – Robottlers Robottler Neo

This project is commissioned by Erasmus.

Team 7 The Crate Robot

Greenline’s crate robot

Greenline’s crate robot is made to fit into the robotic greenhouse system envisioned by cropteq. It transports crates of cucumbers between harvesting robots and the collecting machine in the warehouse.

Team 7 – Greenline The Crate Robot

This project is commissioned by VDL.

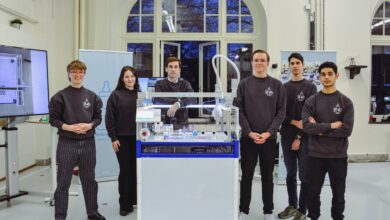

Team 8 Mason

Mason

Mason is an autonomous brick wall jointing robot that alleviates a physically demanding, monotonous task for masons. It scans walls and injects mortar between bricks to finish and renovate facades.

Team 8 – AutoArtisan Mason

This project is commissioned by SMB Geveltechniek.

About the Minor Robotics

The Minor Robotics programme brings bachelor students from Delft University of Technology into contact with all aspects of developing real robots. They work in a multidisciplinary team for a project client and they develop their own robot according to their own market and application research. During the programme, the student teams are based in RoboHouse. On the 23th of January 2025, the seven student teams presented the results of the Minor Robotics during a Demo Day @ RoboHouse. Check out the aftermovie here!

The Minor Robotics 2024-2025 cohort